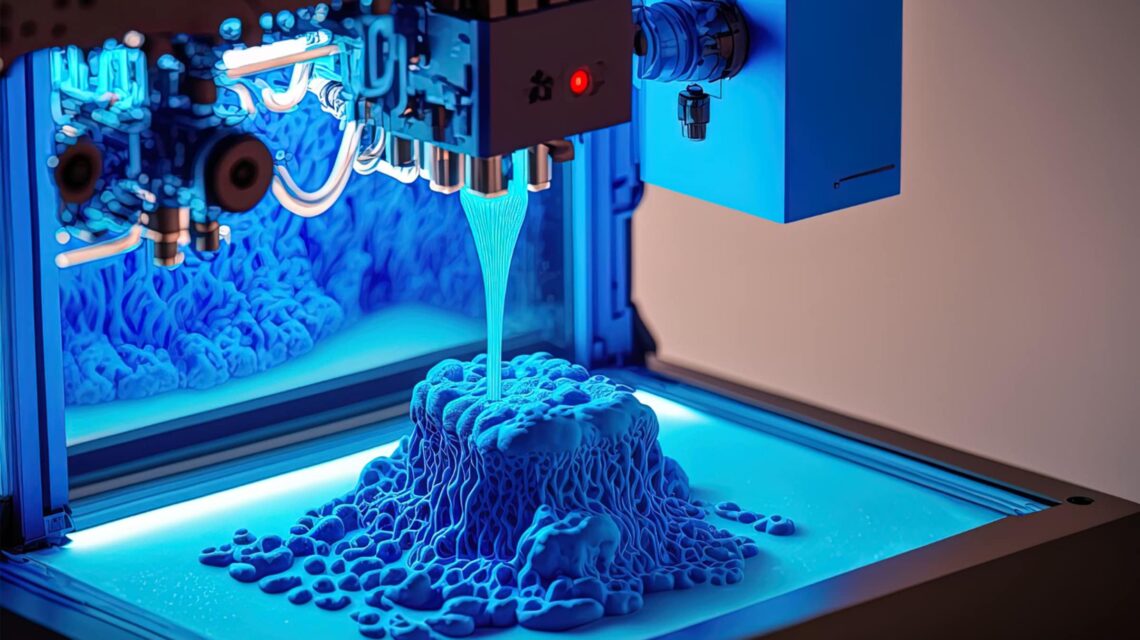

In the world where new tech gets made all the time, smart computer programs and three-dimensional printers have been mixed together to start a fresh time of making things really well. The cool team-up of these two up-to-date ways of doing things offers a chance to change how well and quickly three-dimensional printers can get the job done, even though the work is tricky. While being read with interest, this report digs into how teaching machines to learn can help make three-dimensional printers work with better detail, covering how it changes things for all sorts of businesses.

The Evolution of 3D Printing

First, folks wanted to know how important machine learning in 3D printing was. Just like building a sandcastle one scoop at a time, 3D printers started by making shapes bit by bit. Even though people were excited by what printers could do, they weren’t always spot on with creating things right.

Problems popped up when products weren’t perfect down to the last detail. Because of these hiccups, places that needed things made just so couldn’t always use 3D printers. Guided by computers that learn on the go, 3D printing is now sometimes able to whip up creations with out-of-the-blue cleverness, breathing life into designs unimaginable before.

The Challenges of Precision in 3D Printing

Error margins in the final things were made bigger by unexpected stuff with the stuff used; how hot or cold it got; and tricky settings on the printer machine. Really careful work needed for space, car-making, and where people get fixed wasn’t always done by the old way of printing in 3D. That was a big hurdle for this super cool kind of printing; neatness was so often not met.

Transforming Precision in 3D Printing Jobs

3D printers and AI have joined in a new way, which is quite a change. Big sets of numbers and facts used to draw out smart answers and decisions by AI can now help 3D printers work better. The machines are not as right on target as one might hope for.

These smart AI programs let the 3D printers get better by using info from every print they do. This means each new print could be nearer to perfect – all under the watch of AI. A smart swim under the sea of info and tweaks to keep getting better.

Dynamic Calibration through Machine Learning

Most 3D printers are set up in new ways to be more exact. Old ways to set up the printers often ignore small changes in the stuff they use and the air around them; however, these programs used in computers keep watch over how the printer is doing. They make quick changes so the next thing it prints comes out better.

This computer know-how means things are moving all the time, not stuck in one way of doing things. Crafty changes happen when they need to; Was this printer made better with computer-smarts? That’s what people could ask when they see the surprising results.

Material Recognition and Adaptation

In the world of 3D printing, things being printed just right depend a lot on what the stuff being printed is made of. The clever programs in computers are really good at telling what type of stuff is going into the printer.

Because they can tell the difference, the printer can change how it works for different materials. This means fewer problems when the stuff isn’t always the same, making the things that come out of the printer better and more likely to be right. Unexpected changes mess with the printer less. The entire printing job often ends up much smoother.

Redefining Standards

Precision in 3D printing extends beyond the initial creation of an object to encompass quality control throughout the printing process. Machine learning algorithms excel in real-time monitoring and defect detection. By analysing each layer as it is printed, these algorithms can identify deviations from the desired specifications, enabling prompt adjustments to maintain precision.

Applications Across Industries

With unexpected usefulness, small shapes that hold up well but are not heavy are made by the joining of clever computer thinking and the creation of objects layer by layer in the field where planes and rockets are designed—a sector that demands exact, error-free results. In the world of fixing and treating our bodies, the making of body-part replacements that fit in a way no person of common sense would think possible turns into something that is real. Expert Insights on 2047’s Semiconductor Horizon Car makers are helped too, as they are now able to quickly make early models of their designs, saving both time and what stuff like metal and plastic they use up in the process.

Challenges and Future Prospects

Machine learning has certainly made 3D printing more exact, but there are still hard parts. Some print jobs are tricky and need clever computer programs, which can be tough. Importantly, small companies need to be able to use these better ways or tools, which must be thought about. Lastly, the road ahead has many cool chances for machine learning to get even better at 3D printing. With machine learning, 3D printers get better at doing their job, by this the good steps happening in this area are shared.

Conclusion

Robots and 3D printers are teaming up. This team-up is changing how we make stuff, really well. Many people and factories didn’t use 3D printers much before, because things often came out sloppy, but now, robots help make them much better and more perfect.

A fresh read titled “Precision Perfected” talks about the big change. It says that robot and printer pals are very important together. The book tells us just how this latest buddy-up will change things, making sure things made by 3D printers are now done with great care and a wow factor, for jobs all over.

Robotics Efficiency: Optimal Object Packing

Robotics Efficiency: Optimal Object Packing  Daron Acemoglu Wins A.SK Social Science Award

Daron Acemoglu Wins A.SK Social Science Award  AI Learning: The Power of Synthetic Imagery

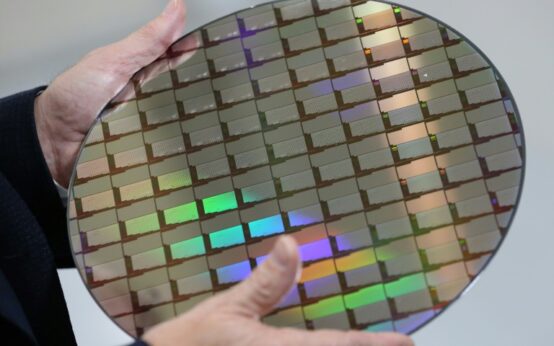

AI Learning: The Power of Synthetic Imagery  Expert Insights on 2047’s Semiconductor Horizon

Expert Insights on 2047’s Semiconductor Horizon  Desalination’s Triumph Over Batteries

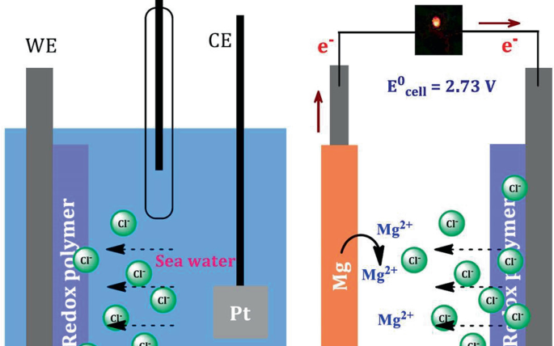

Desalination’s Triumph Over Batteries  Mastering Digital Footprint: Ways to Targeted Ads

Mastering Digital Footprint: Ways to Targeted Ads